Forwa·Quality Strength

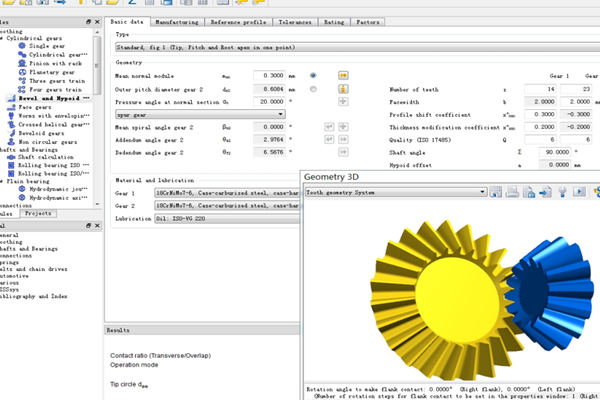

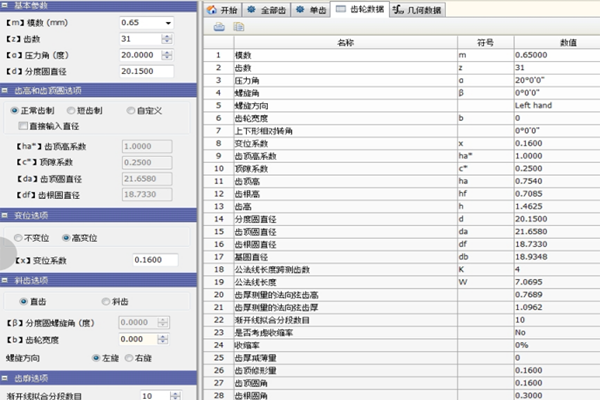

Gear inspection center : The gear inspection center is a fully automatic measurement equipment for gear error items using high-precision shafting, probes, and gratings. Used to detect spur gear tooth profile, tooth pitch deviation, pitch accumulation, radial runout and other gear errors

OSAKA gear meshing instrument : It is a double-sided gear meshing measuring instrument. The main work is to use the meshing test between the "standard gear" and the "product gear" to measure the change of the distance between the axes of the two gears as the measurement accuracy error. . It can measure the comprehensive radial deviation, judge whether there are knock marks, tooth contact, radial runout, backlash, etc. It is suitable for grading judgment of quality standards such as JIS/ISO/AGMA/DIN/JGMA.

3-dimensional measuring instrument : Using element calculation, high-precision grating, and guide rail, the detection accuracy reaches 0.002mm, equipped with software, realizes automatic detection, and greatly improves the detection efficiency

Certificate qualification : ISO9001,ISO14001,IATF16949