-

Please email to sales@forwa-gear.com or fill out the contact form below:

- Home

- Capabilities

- Plastic Injection

- Plastic Gear

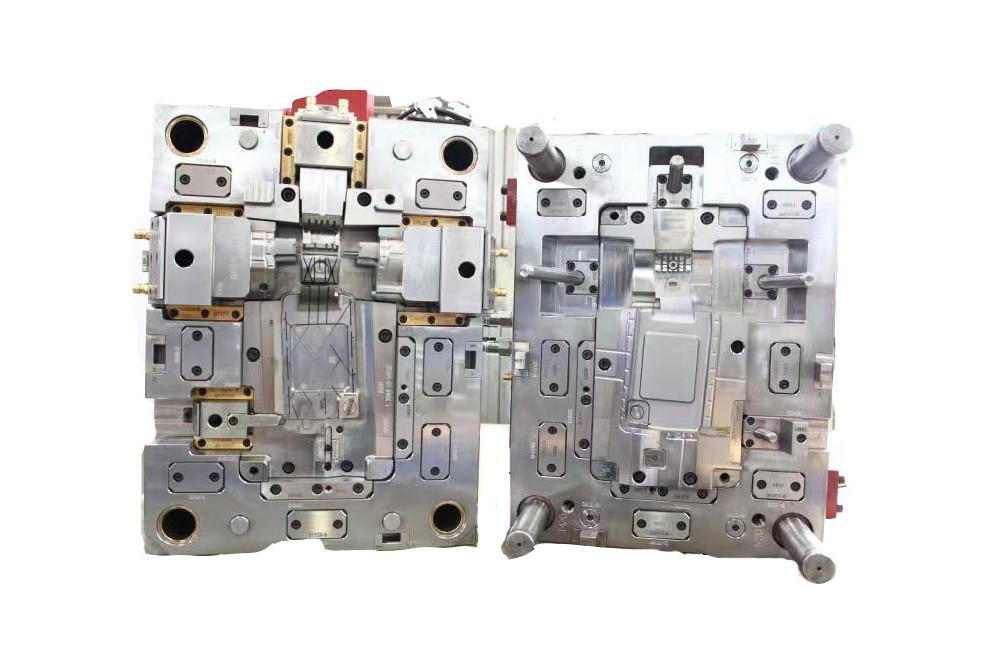

- Plastic Mold

- DC Gear Motor

- Solutions

-

-

Electric mop gearbox solution

Concealed door handle gearbox transmission mechanism

Dragon claw massager gear reducer solution

Electric bath brush gearbox solution

The solution of the gear reducer of the tooth punch

Sweeping robot gearbox solution

Electric curtain tubular motor gear reducer solution

Solution of planetary gear reducer for automobile electric tailgate strut

-

- News

- About

- Contact