Product parameters

Why Us

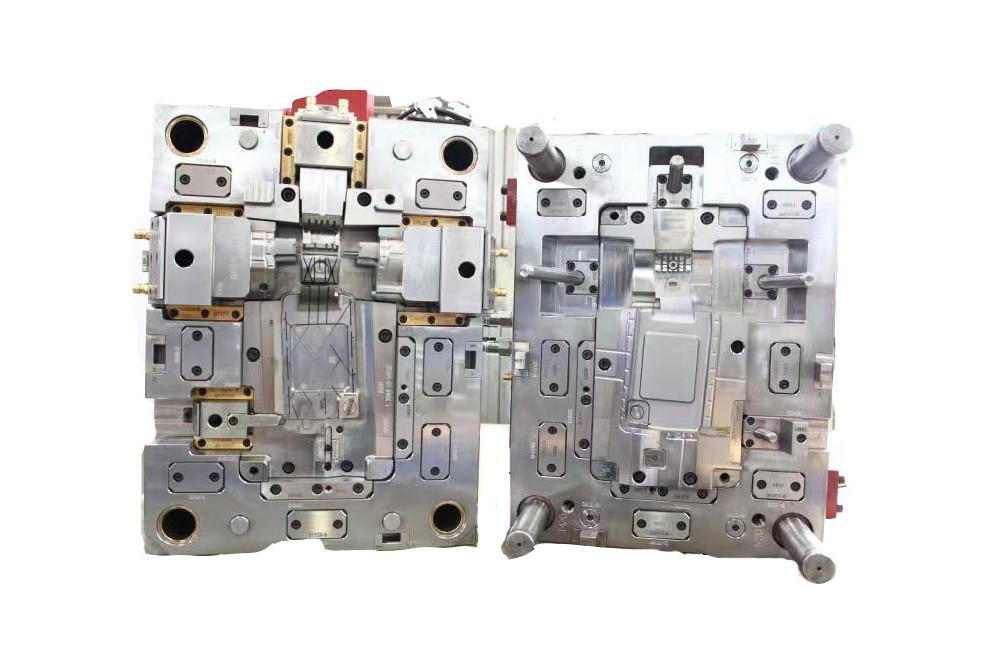

20+ Years Experiences in Plastic Mold Injection Molding Making

-

-

Injection Processing Equipment

10 Injection molding machines imported from Japan, including Funac injection molding machine, Nissei machining center,

4 Injection molding machines imported from Germany, including 4 Arburg injection molding machines

8 Injection molding machines imported from Taiwan

10 Haitian precision injection molding machines

-

-

Plastic Product Testing Equipment

Hexconn imported from the United States is three times a set

Mitutoyo imported from Japan is 3 times a set

One Osaka gear meshing instrument imported from Japan

Two Mitutoyo tool microscopes imported from Japan

One Tesa height gauge imported from the United States

2 sets of Eason imported from Taiwan

Harbin Jingda Gear Inspection Center 1 set

Request Quote

Personnel Introduction

We Are Relied Upon And Trusted By Our Customers, And We Are Recognized By Them For Our High Quality Products And Attentive Service

Dongguan Forwa Precision Industrial Technology Co., Ltd. has been established for 20 years, focusing on injection molding of small and medium-sized precision plastic parts. Its customers are located in Japanese-funded enterprises in Europe, the United States and the Pearl River Delta. The product fields involve printers, plastic gears for photocopying and internal structures. parts, auto parts, consumer electronics, industrial electronics, optical fiber communications, medical equipment and sports equipment. The types of injection molding involved include plastic gear injection molding, single-color plastic mold injection molding, rubber-coated mold injection molding, insert molding mold injection molding, thread core-pulling plastic mold injection molding, etc. The company has passed ISO9001 and ISO14001, IATF16949.